Overview:

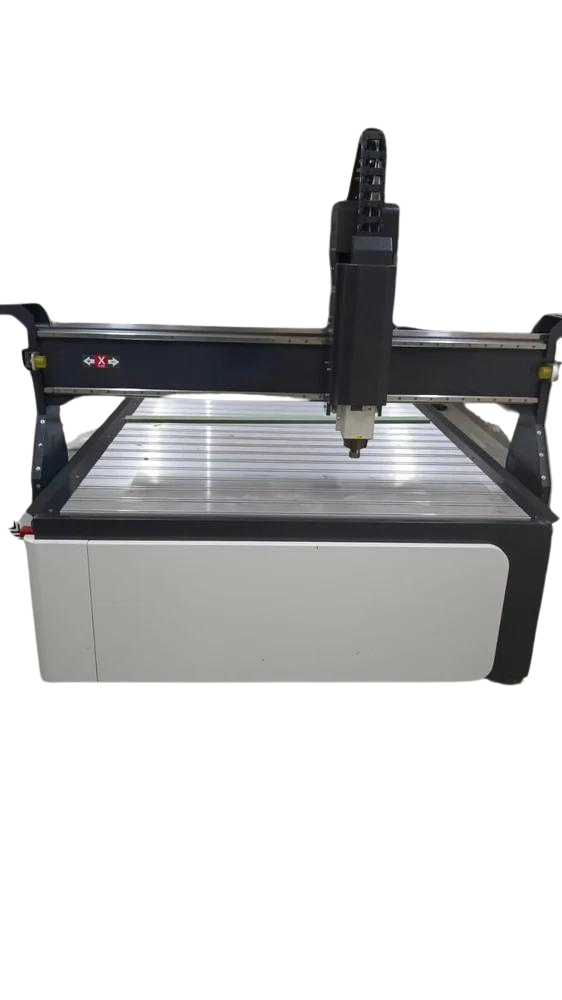

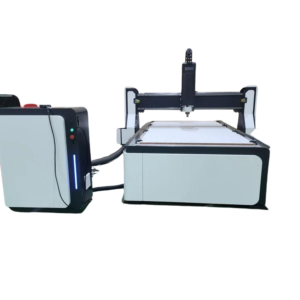

- Model: CNC Router 5×12

- Working Area: 5 feet x 12 feet (1524 mm x 3658 mm)

- Primary Use: Cutting, carving, and milling large sheets of materials such as wood, plastics, composites, and soft metals.

Key Features:

- Cutting Area:

- The 5×12 configuration provides a large working area of 1524 x 3658 mm. This ample space allows for the processing of large panels or multiple smaller pieces in one setup, making it ideal for commercial and industrial applications.

- Spindle Power:

- Typically equipped with a spindle ranging from 3 kW to 7.5 kW or more, depending on the material and application. The spindle power allows for efficient cutting and carving of various materials, including hardwood, softwood, MDF, and some soft metals.

- Precision and Accuracy:

- Features high-precision components such as linear guides, ball screws, and high-torque motors. These elements ensure accurate and repeatable results, crucial for detailed work and maintaining consistent quality over large projects.

- Controller:

- Operated via a CNC system that allows for detailed programming and automation. The controller often includes a user-friendly interface, such as a touchscreen, which makes it easier to manage operations and monitor the cutting process.

- Software Compatibility:

- Compatible with various CAD/CAM software programs, allowing users to create and import designs, generate tool paths, and control the router with high precision. This software integration supports complex and custom machining tasks.

- Frame and Build:

- Constructed with a heavy-duty frame, usually made from steel or aluminum, to provide stability and minimize vibrations during operation. The solid build helps in achieving precise cuts and maintaining the machine’s longevity.

- Tooling Options:

- Can be equipped with a range of tools and bits, such as straight bits, ball end mills, and V-bits, to handle different cutting and carving needs. Many models also feature an automatic tool changer for enhanced efficiency and versatility.

- Material Handling:

- Includes features for efficient material handling, such as vacuum tables or mechanical clamping systems to secure the material in place during operation. This ensures stability and accuracy while cutting or carving.

- Dust Collection:

- Many CNC routers come with integrated dust collection systems to manage the debris generated during cutting and carving. This keeps the work area clean and protects the machine’s components from dust buildup.

- Safety Features:

- Equipped with safety mechanisms such as emergency stop buttons, protective enclosures, and safety interlocks to ensure safe operation and prevent accidents.

Applications:

- Woodworking: Ideal for cutting, carving, and milling large panels or sheets of wood, making it suitable for furniture, cabinetry, and decorative pieces.

- Sign Making: Used to create large-scale signs, displays, and custom graphics with precision.

- Manufacturing: Suitable for producing components and parts from various materials, including composites and soft metals.

- Architectural Elements: Ideal for crafting architectural features such as moldings, panels, and decorative elements.

- Prototyping: Useful for creating prototypes and models in various industries, including automotive, aerospace, and consumer goods.

Benefits:

- Large Working Area: The 5×12 size accommodates large materials and projects, improving productivity and efficiency for big jobs.

- High Precision: Delivers accurate and detailed cuts, essential for professional and high-quality results.

- Versatility: Capable of handling a wide range of materials and applications, making it suitable for diverse industries and projects.

- Efficiency: Automates the cutting and carving process, reducing manual labor and increasing production speed.

Reviews

There are no reviews yet.