Overview:

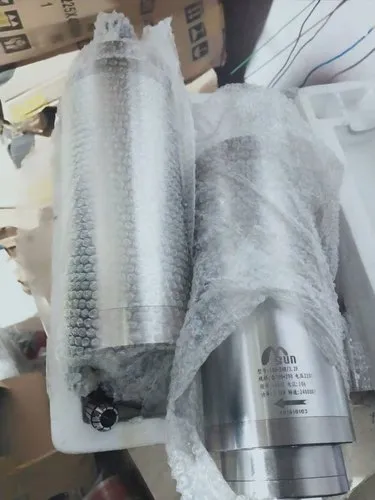

- Type: CNC Router Spindle

- Primary Use: Provides rotational power to the cutting tool or bit for machining materials such as wood, plastic, and metal.

Key Features:

- Construction and Materials:

- Housing: Typically made from high-strength materials such as aluminum, steel, or cast iron. The housing is designed to withstand high-speed operation and mechanical stresses.

- Rotor and Stator: Contains the rotor (rotating part) and stator (stationary part) which work together to produce rotational motion.

- Power Ratings:

- Power Range: Spindles come in various power ratings, generally from 0.8 kW to 15 kW or more. The power rating influences the spindle’s ability to handle different materials and cutting tasks.

- Selection: Power requirements depend on the material being machined and the specific demands of the CNC router.

- Speed Range:

- RPM: Spindles offer a range of rotational speeds, typically from 6,000 RPM to 24,000 RPM or higher. Adjustable speed settings allow for optimization of cutting performance based on material and tooling.

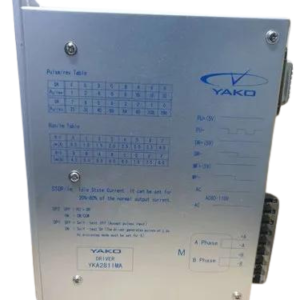

- Control: Speed can be controlled manually via a variable speed drive or automatically via the CNC machine’s control system.

- Cooling Systems:

- Air-Cooled Spindles: Use air flow to dissipate heat generated during operation. They are simpler and require less maintenance but can be noisier.

- Water-Cooled Spindles: Use a water-cooling system to maintain optimal operating temperatures. They are quieter and more efficient for longer and more demanding operations but require additional plumbing and maintenance.

- Tool Holders and Collets:

- Tool Holders: Spindles use tool holders or collets to secure the cutting tools. Common types include ER collets, ISO collets, and other specialized holders.

- Interchangeability: Different sizes and types of collets can be used to accommodate various tool diameters and types.

- Mounting and Compatibility:

- Mounting Options: Spindles are mounted onto the CNC router using brackets or flanges. The mounting system must align with the machine’s spindle mount to ensure proper operation.

- Compatibility: Spindles must be compatible with the CNC router’s motor, control system, and tool holder to function correctly.

- Performance Characteristics:

- Precision: Designed to deliver high precision and accuracy in cutting, carving, and engraving operations.

- Durability: Built to withstand high-speed operation and the mechanical stresses of cutting and machining.

- Noise Levels:

- Operation: Air-cooled spindles may be noisier due to the operation of cooling fans. Water-cooled spindles are generally quieter due to the more effective heat dissipation.

- Maintenance:

- Routine Checks: Regular inspection of the spindle for wear, noise, and alignment is essential.

- Lubrication: Some spindles require periodic lubrication to maintain smooth operation and prolong lifespan.

- Cooling System Maintenance: For water-cooled spindles, ensuring proper coolant levels and checking for leaks is crucial.

Applications:

- Woodworking: Ideal for cutting, carving, and engraving wood, MDF, and other similar materials.

- Plastic Machining: Suitable for processing various plastics such as acrylic, PVC, and polycarbonate.

- Metalworking: Used for light-duty machining of metals like aluminum and brass.

- Engraving: Perfect for detailed engraving on a variety of materials, including stone, metal, and plastics.

Benefits:

- Precision and Accuracy: Provides high precision and accuracy in cutting and engraving operations, essential for achieving detailed and high-quality results.

- Versatility: Capable of handling a wide range of materials and cutting tasks, making it versatile for different applications.

- Performance: Delivers consistent performance and reliability, contributing to the overall efficiency and effectiveness of the CNC router.

- Flexibility: Adjustable speed and power settings allow for customization based on the specific requirements of the task.

Reviews

There are no reviews yet.