Overview:

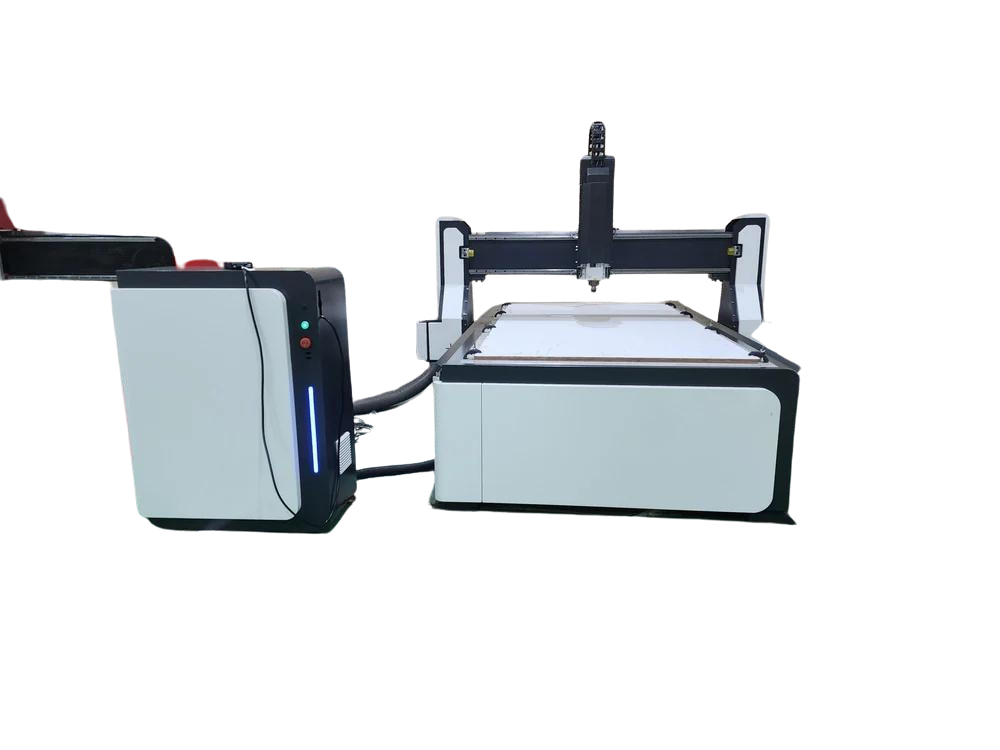

- Type: CNC Cutting Machine

- Primary Use: Automated cutting of materials such as wood, metal, plastic, fabric, and composites.

Key Features:

- Cutting Area:

- The cutting area varies depending on the model and can range from small desktop sizes (e.g., 300 x 300 mm) to large industrial sizes (e.g., 3000 x 1500 mm or more). This determines the maximum size of the materials and projects the machine can accommodate.

- Spindle/Tool Power:

- Spindle Power: For cutting hard materials like metals, the spindle power can range from 1.5 kW to 10 kW or more. For softer materials like wood or fabric, the power might be lower.

- Tooling Options: Depending on the material, machines may use various tools such as high-speed spindles, laser cutters, plasma torches, or water jets.

- Precision and Accuracy:

- Features high-precision components such as linear guides, ball screws, and stepper or servo motors to ensure accurate cutting. This precision is crucial for intricate designs and maintaining high-quality results.

- Controller:

- Operated via a CNC (Computer Numerical Control) system, which allows for detailed programming and automation. The controller is typically equipped with a user-friendly interface, often a touchscreen, for ease of operation and monitoring.

- Software Compatibility:

- Compatible with various CAD/CAM software programs. This compatibility allows users to design and import files, generate tool paths, and control the cutting process with precision.

- Frame and Build:

- Constructed with a robust and heavy-duty frame, usually made from steel or aluminum, to ensure stability and minimize vibrations. This construction is critical for maintaining accuracy during the cutting process.

- Cutting Methods:

- Laser Cutting: Uses a high-powered laser beam to cut through materials. Ideal for precise cuts and detailed designs.

- Plasma Cutting: Employs a plasma torch to cut through electrically conductive materials like steel and aluminum.

- Water Jet Cutting: Utilizes a high-pressure stream of water mixed with abrasives to cut through various materials. Suitable for materials sensitive to heat.

- Router Cutting: Uses a spinning router bit to cut through materials. Commonly used for wood and plastics.

- Automation Features:

- Automatic Tool Changer: Allows the machine to switch between different tools or bits automatically, enhancing efficiency.

- Material Handling: Some machines include automated material feeding systems, such as conveyor belts or rotary tables, to streamline the cutting process.

- Safety Features:

- Equipped with safety mechanisms such as emergency stop buttons, protective covers, and interlock systems to ensure safe operation.

- Dust and Debris Management:

- Many models include integrated dust collection systems to manage debris generated during cutting, keeping the workspace clean and extending the life of the machine components.

Applications:

- Woodworking: Cutting and shaping wood for furniture, cabinetry, and decorative items.

- Metal Fabrication: Cutting metal sheets and plates for industrial and manufacturing applications.

- Signage: Creating custom signs and graphics from various materials.

- Textile Industry: Cutting fabrics and textiles for garment manufacturing and other applications.

- Prototyping and Production: Used in various industries for prototyping and manufacturing parts and components.

Benefits:

- High Efficiency: Automates cutting processes, increasing productivity and reducing manual labor.

- Versatility: Capable of cutting a wide range of materials with precision, making it suitable for diverse applications.

- Precision: Provides high accuracy in cutting, essential for detailed and professional results.

Reviews

There are no reviews yet.