Overview:

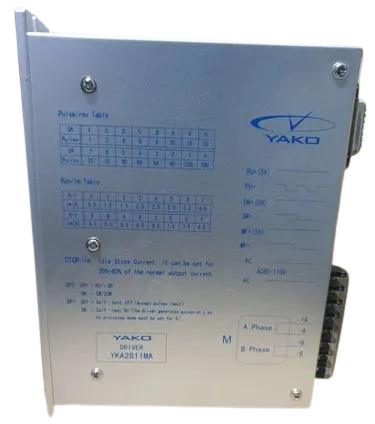

- Model: Yako YKA2811MA

- Type: Microstep Driver

- Primary Function: Controls stepper motors by converting input control signals into precise electrical currents, allowing for accurate and smooth motor movement.

Key Features:

- Microstepping Technology:

- Microstepping Resolution: Supports high microstepping resolutions, allowing the motor to move in very fine increments. This results in smoother operation and reduced vibration compared to full-step or half-step driving.

- Step Modes: Typically includes various step modes, such as 1/2, 1/4, 1/8, and 1/16, providing flexibility for different applications and precision requirements.

- Current Control:

- Current Regulation: Features advanced current regulation to optimize the current supplied to the stepper motor. This helps prevent overheating and ensures efficient motor performance.

- Adjustable Current Settings: Allows users to set the maximum current according to the motor specifications, which helps in matching the driver’s output with the motor’s requirements.

- Voltage and Power Ratings:

- Voltage Range: Operates within a specific voltage range suitable for the stepper motor being used, typically from 12V to 48V or higher.

- Power Rating: Designed to handle various power levels depending on the motor’s requirements and the application’s needs.

- Input Signals:

- Pulse and Direction Inputs: Receives pulse signals to determine the step position and direction inputs to control the rotation direction of the stepper motor.

- Control Interface: Interfaces with a variety of control systems such as CNC controllers, PLCs (Programmable Logic Controllers), or other motion control systems.

- Protection Features:

- Overcurrent Protection: Protects against excessive current, which can damage the driver or the motor.

- Overtemperature Protection: Monitors the driver’s temperature and reduces performance or shuts down if it gets too hot, preventing overheating.

- Short Circuit Protection: Includes safeguards to prevent damage from short circuits within the driver or motor wiring.

- Performance Characteristics:

- Smooth Operation: Provides smooth and precise control of the stepper motor, reducing noise and vibration through effective microstepping.

- High Precision: Enables high-resolution control, making it suitable for applications that require accurate positioning and motion.

- Configuration and Tuning:

- Adjustable Settings: Users can adjust various settings such as microstepping resolution, current limits, and decay modes to fine-tune performance.

- Programming: Typically does not require extensive programming but allows for configuration through DIP switches or other interface methods.

- Heat Dissipation:

- Cooling: Includes heat sinks or other cooling mechanisms to manage the heat generated during operation and ensure stable performance.

Applications:

- CNC Machines: Used in CNC milling, routing, and engraving machines for precise control of machine axes.

- 3D Printers: Controls the movement of print heads and build platforms for accurate additive manufacturing.

- Robotics: Drives stepper motors in robotic systems for precise positioning and movement.

- Automated Systems: Suitable for various automated systems requiring accurate and reliable motor control.

Benefits:

- Precision Control: Provides accurate and smooth control of stepper motors, enhancing the performance of CNC machines and other systems.

- Reduced Vibration: Microstepping reduces vibration and noise, resulting in a quieter and more stable operation.

- Efficiency: Advanced current control improves efficiency and reduces heat generation, contributing to longer motor and driver lifespan.

- Flexibility: Compatible with various stepper motors and control systems, offering versatility for different applications.

Maintenance and Care:

- Regular Inspection: Check for signs of overheating, wear, or damage to ensure proper operation.

- Cooling: Ensure that cooling mechanisms are functioning correctly to prevent overheating.

- Connections: Inspect electrical connections and wiring for signs of wear or damage, and ensure proper alignment.

Reviews

There are no reviews yet.