Overview:

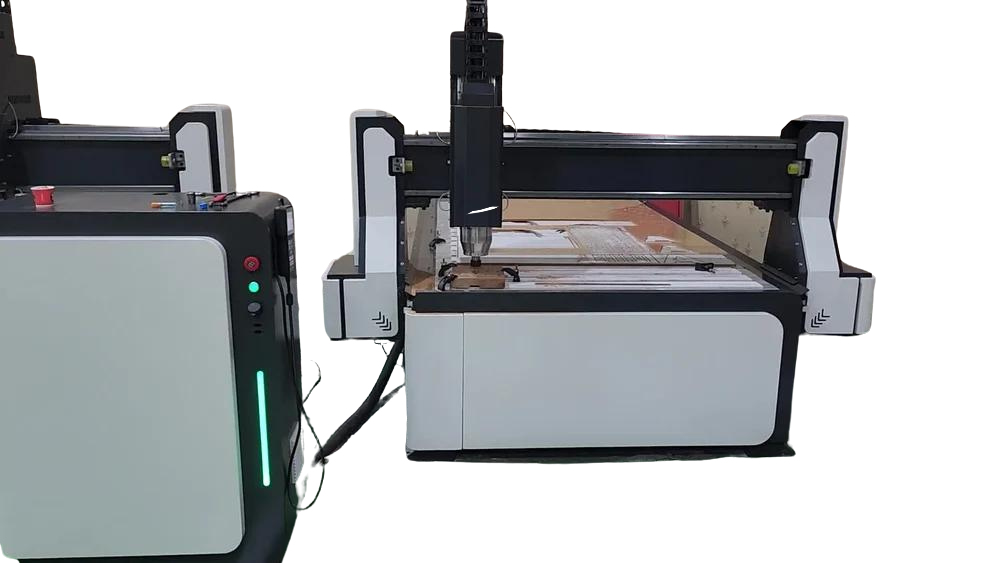

- Type: CNC Engraving Machine

- Primary Use: Engraving detailed designs, text, and patterns on materials such as metal, wood, plastic, glass, and more.

Key Features:

- Engraving Area:

- The size of the engraving area varies depending on the model but typically ranges from smaller sizes (e.g., 300 x 300 mm) for detailed work to larger sizes (e.g., 1000 x 1500 mm) for bigger projects. The engraving area defines the maximum dimensions of the material that can be processed.

- Spindle/Tool Power:

- Spindle Power: Generally ranges from 0.5 kW to 3 kW, depending on the material being engraved. Higher spindle power is used for tougher materials and for achieving finer details.

- Tools: Uses various engraving tools such as diamond bits, V-bits, and end mills, designed to achieve different effects and depths of engraving.

- Precision and Accuracy:

- Equipped with high-precision components like linear guides, ball screws, and high-resolution stepper or servo motors. These ensure detailed and accurate engraving, which is essential for intricate designs and high-quality results.

- Controller:

- Operated via a CNC system that controls the movement of the spindle and tool based on a programmed design. The controller often features a user-friendly interface, typically a touchscreen, to facilitate easy operation and programming.

- Software Compatibility:

- Compatible with a range of CAD/CAM software programs that allow users to create detailed designs, generate tool paths, and control the engraving process. This integration supports precise and customized engraving work.

- Frame and Build:

- Constructed with a robust and stable frame, usually made from materials like steel or aluminum, to reduce vibrations and maintain accuracy. The rigidity of the frame is crucial for achieving high-quality engravings.

- Engraving Methods:

- Rotary Engraving: Uses a rotating spindle with engraving bits to carve designs into the material.

- Laser Engraving: Employs a laser beam to engrave designs with high precision. This method is commonly used for detailed work on materials like glass and metal.

- Mechanical Engraving: Utilizes mechanical tools to cut and carve into the material, often used for metal and harder substrates.

- Automation Features:

- Automatic Tool Changer: Some models include automatic tool changers that allow the machine to switch between different engraving tools without manual intervention.

- Material Handling: Features such as automated material feeding and positioning systems to streamline the engraving process and improve efficiency.

- Cooling and Dust Management:

- Cooling Systems: Water or air cooling systems may be used to manage heat generated during engraving, particularly for high-speed operations or hard materials.

- Dust Collection: Integrated dust extraction systems to keep the workspace clean and protect machine components from debris.

- Safety Features:

- Equipped with safety mechanisms such as emergency stop buttons, safety covers, and interlock systems to ensure safe operation and prevent accidents.

Applications:

- Signage: Creating custom signs, plaques, and nameplates with detailed text and designs.

- Jewelry Making: Engraving intricate patterns and designs on jewelry pieces.

- Awards and Trophies: Customizing awards, trophies, and medals with personalized engravings.

- Industrial Parts: Engraving serial numbers, logos, and other markings on industrial components.

- Artistic Work: Producing detailed engravings for decorative and artistic purposes.

Benefits:

- High Precision: Achieves detailed and accurate engravings, essential for professional and high-quality results.

- Versatility: Capable of engraving a wide range of materials with different techniques, making it suitable for various applications.

- Efficiency: Automates the engraving process, reducing manual effort and increasing production speed.

Reviews

There are no reviews yet.